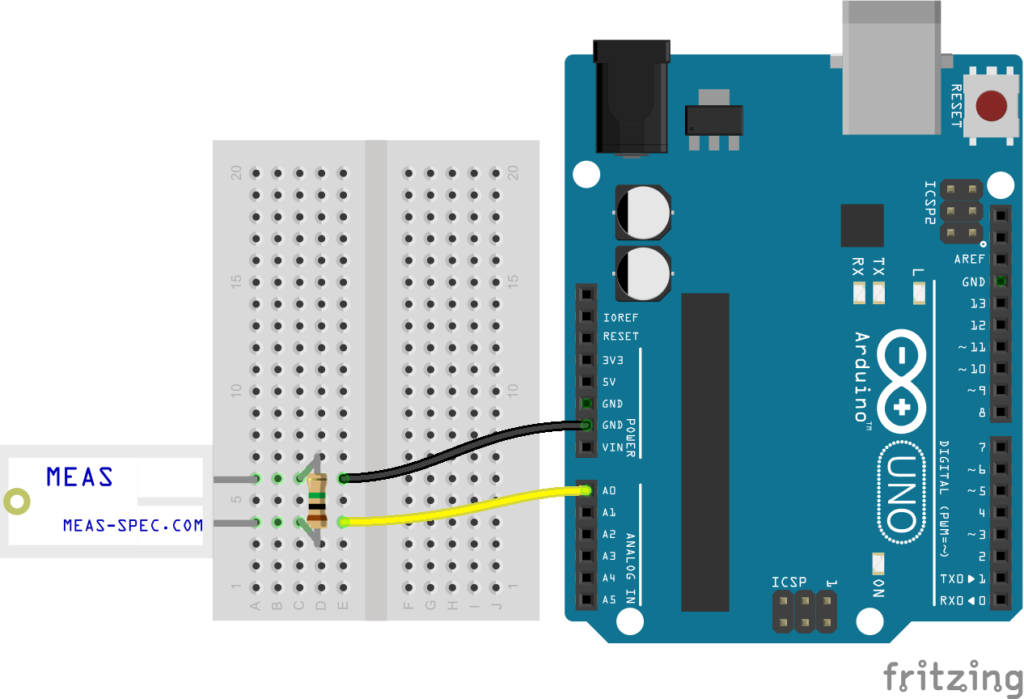

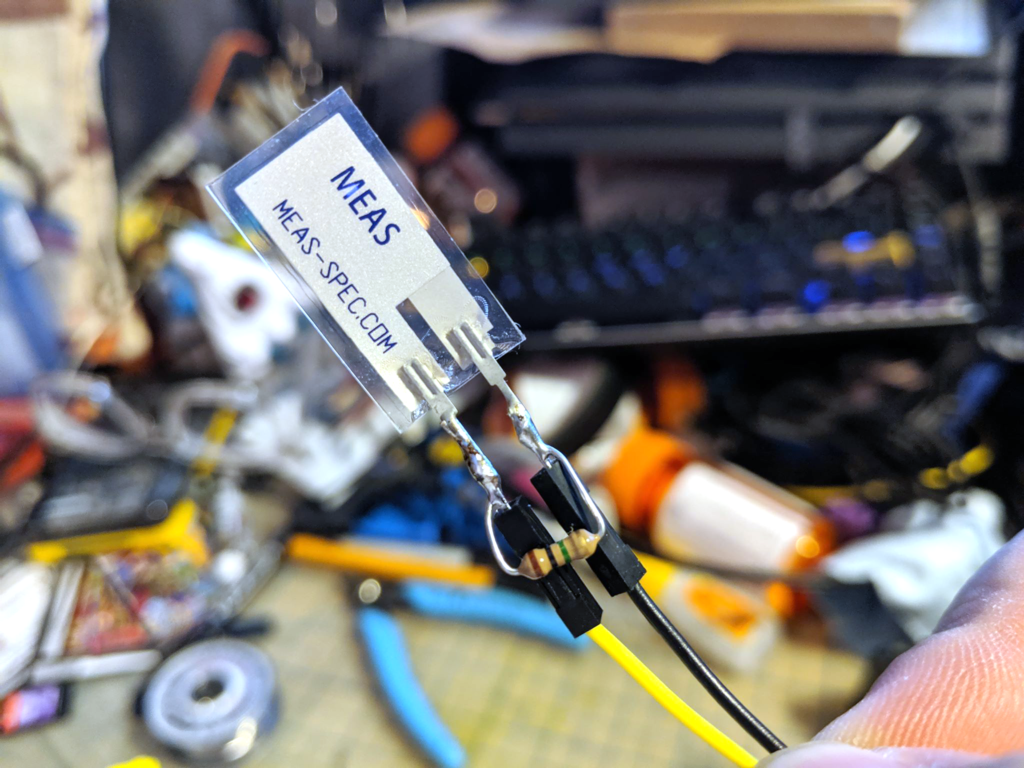

This basic piezo sensor from Measurement Specialties is often used for flex, touch, vibration and shock measurements. A small AC and large voltage (up to +/-90V) is created when the film moves back and forth. A simple resistor should get the voltage down to ADC levels. Can also be used for impact sensing or a flexible switch (sparkfun).

Where is a 1M Ohm resistor when I need one. I found them in school, Design and Technology rocks!

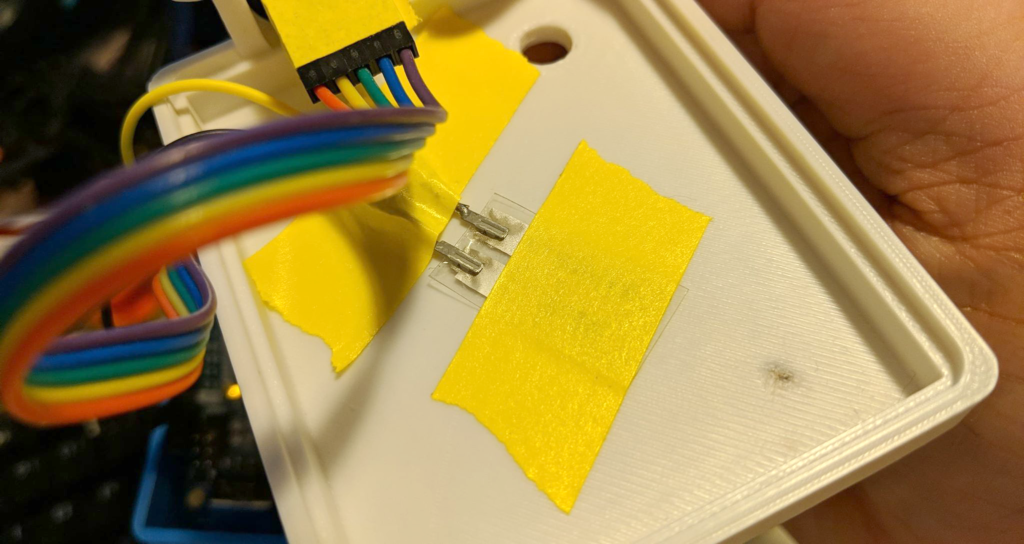

This 12 year-old sensor works like magic. After some preliminary tests, I am taping it to the inside of my wind sensor box. Now besides blowing air, I have another input to play with.

It is a bit tricky to combine code for both wind sensor and MEAS vibration sensor. Wind sensor’s official Arduino sample code requires a 200 ms delay. I am not going to touch that since it works so well. However, when I included the analogRead for MEAS inside of the 200 ms cycle, I can’t get the reading accurately. This is because when I tap the surface, the number goes up and down so quickly that a check every 200 ms will most likely miss the peak moment.

My solution is to check MEAS as frequently as possible and remember the peak value. When I read the wind sensor every 200 ms, I also check if there is a peak value available. If so, I will send alone the peak value and reset it for the next peak moment.